Steel is an alloy of iron (Fe) and carbon (C) as well as some other alloying elements, depending on the required properties. However, steel is just a generic term representing thousands of products encompassing a great variety of compositions, shapes and qualities. There are over 3,000 catalogued grades (chemical compositions) not counting those created to meet custom demand and research applications.

Steel is known to be one of the most versatile materials of the modern age. Nowadays, the use of steel in many industrial applications is a common standard due to its mechanical properties and low production costs.

Virtually everything contains steel: machines, trains, tracks, buildings, automobiles, aircrafts and spacecrafts. Below the ground, miles upon miles of steel tubes and pipes carry water and protect telephone and electric power cables. In our homes, iron and steel is ever-present. Steel is the backbone of our present and the foundations for our future.

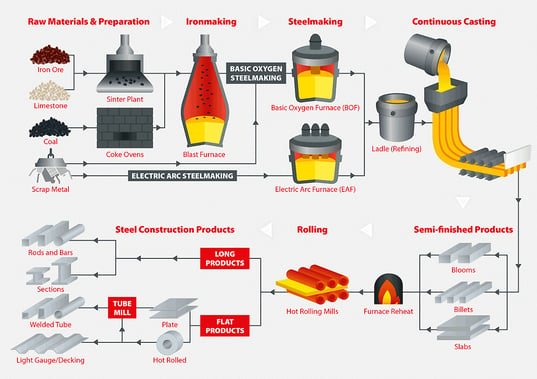

All these different products, regardless of the application, have a similar production scheme. Steel production starts with the transformation of the raw materials into a semi-finished product, and from this point on, the particular final form will be generated according to the desired function.

It is possible to produce both steel beams for construction, or particular automotive parts from the same semi-finished product.

How steel is made.

First, the raw materials, either iron ore or scrap iron (depending on the process), are converted into molten steel. The ore-based process uses a blast furnace or smelter and the scrap-based process uses an electric arc furnace.

Next, the molten steel is poured and solidified in a continuous caster. This produces what we have mentioned before as semi-finished products. These can be either slabs, which have a rectangular cross-section, blooms or billets, which have a square cross-section.

Lastly, these blank products are used to form a finished product. Depending on the particular geometries required, some will need to undergo heat treatment to achieve particular mechanical properties.